Aug 4, 2023

How drone surveys take the guesswork out of site inspections

According to the Construction Institute, the average cost of rework on industrial projects wastes US $17b annually.

Drone surveys are helping to change that.

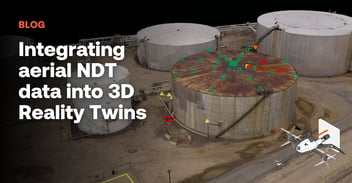

Drone photogrammetry used with Trendspek's 3D technology helps surveyors receive accurate site specs within 24 hours for more informed decision-making and maintenance planning.

A single drone flight collects tens of thousands of images which are then processed, or "stitched" together, by Trendspek's software to create an exact 3D model of the site – a Reality Twin.

What is a Reality Twin, and how is it different from other digital twins?

First introduced by Trendspek in 2021, the Reality Twin was designed to deliver better outcomes across various industries managing large-scale infrastructure and buildings.

Reality Twins consider the intricate needs of the asset management industry, to provide 3D models that drive safety, deliver accuracy, and empower certainty. Capitalising on modern capture methods and greater processing power, those tens-of-thousands of data points (images) are transformed into the world’s most detailed asset models, accurate to the millimetre.

3D and interactive, these models are hosted in secure cloud-based storage, enabling stakeholders from around the globe to collaborate in real-time, mark up, measure and annotate with comprehensive digital record-keeping of assets.

.gif?width=400&height=252&name=Landing%20Page%20Reel%20PAI%20(1080%20x%20780%20px).gif)

The benefit of Reality Twins

Just one Reality Twin can deliver multiple layers of value across the entire lifecycle, allowing for virtual defect identification, streamlined scope and tendering, remediation planning, interactive reporting in real-time and active monitoring.

With access to an accurate digital record of the structure within a user-friendly interface minimises the need for engineers and contractors to physically visit the site.

Below, we explore the use of Reality Twins across various industries, from critical infrastructure to commercial real estate

Working alongside Placemaking NSW, CBRE and other key project stakeholders, Trendspek provided highly-detailed 3D models of the White Pay Power Station ahead of major remediation works and adaptive reuse for Sydney Biennale 2024.

"What began as a need for a traditional report and photos, led to the ability to virtually fly around to look at different aspects of the asset that we were unable to physically reach and inspect. On a site that requires such extensive conservation works, having the ability to easily inspect out of the way areas was invaluable."

Fulcrum, a leading robotics service provider, use Trendspek to deliver full structural context and thermal monitoring of large dams in Tasmania, Australia.

“Large dams can be really dangerous if they aren’t managed well. The models we provide are so detailed and so accurate, that the client didn’t need to engage a lot of roped contractors to undertake a detailed inspection of the asset. The model was able to show us and the client where the issues were, and they were then able to target physical inspections, if required."

PGIM Real Estate is committed to innovation across real estate investment. The Australian arm piloted Trendspek in 2020, using it to transform the due diligence process for commercial assets.

"We're using Trendspek because of its thoroughness, accuracy and the speed it lends to the due diligence process. Before, we’d have a team of abseilers but now, we have one drone operator and we can capture a substantial building in less than a day. Effectively, within a few days of drone capture, we can be looking at imagery of a full building."

For over 40 years, Wallbridge Gilbert Aztec or WGA has been a trusted engineering leader in Australia, regularly conducting inspections across large mechanical, structural and maritime assets. They first adopted Trendspek to transform the inspection process for a fleet of container cranes, with key efficiency gains.

“It cut down capture time from three days to one, but driving factor behind our decision to use Trendspek was safety of our people and safety for the client. We now have a digital capture of the assets so we can go back and inspect any time, even if we missed that traditional three-day shutdown window. The detail on screen means it’s just like being there, if not better.”

Infracorr Consulting is a trusted expert in Australia for managing complex concrete repairs. They adopted Trendspek to transform durability solutions across industrial, maritime and education sectors.

“In the past we would not have ever closely surveyed 100% of structures like the silos, due to the time and cost of inspections from ropes or access booms. With Trendspek, we get the drone capture in a couple of days, with the complete tagging of defects done on our computer screens in a few weeks. Using the marked-up model, we investigate in detail selected defects using traditional access and our skilled engineers."

Ready to explore Trendspek?

Our team is ready to help you achieve these outcomes. Let's make it happen.